In the recently published ‘Manufacturing bioinspired flexible materials using ultrasound directed self-assembly and 3D printing,’ researchers from the University of Utah are exploring a new process for engineering materials with innovative substructures that help tune mechanical properties.

Previous research has resulted in integrated microstructures brought on by nature’s designs for improved biological materials with improved properties overall. In the past, other research labs have used electrical properties with polymers, a variety of actuators, and more.

Hierarchical microstructures have been created via:

- Stereolithography (SLA)

- Traditional mold casting

- Freeze casting

“Electric fields in combination with molding microwires from colloidal suspensions of metallic nanoparticles in water have also been used. These fabrication methods enable manufacturing of homogeneous composite materials and some have been combined with 3D printing, including electric field printing, shear force assisted 3D printing, and bioinspired 3D printing,” explain the researchers.

“However, these fabrication techniques place strict requirements on material choice, possible material geometry, and dimensional scalability, often requiring ultra-high field strengths. Thus, they may limit the potential properties and usefulness of the resulting engineered materials.”

In this study, the research team creates a new direct-writing process for 3D printing. Using a syringe, liquid feedstock is extruded, with ultrasound DW controlling the creation of the microstructure.

The researchers used a Cartesian-style RepRap Guru 3D printer in this study, replacing the print head with a custom syringe designed in their lab, and meant for photopolymer resins. They created three syringes, all modified with custom nozzles.

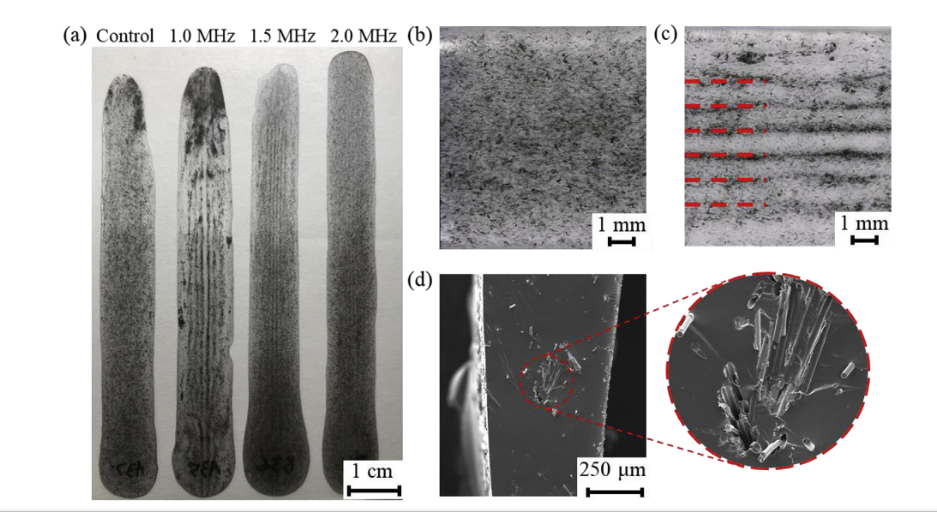

“These custom nozzles were driven by a function generator and 45 dB RF amplifier (ENI 440LA, Rochester, NY, USA), to perform ultrasound directed self-assembly of microscale nickel-coated car-bon fibers (NCCFs) (100mm length, 10mm diameter, Conductive Composites, Heber City, UT, USA) dispersed in the photopolymer resin, into discontinuous line patterns,” explain the researchers.

In creating samples, feedstock was exposed to waves of:

- MHz

- 5 MHz

- 0 MHz

Piezoelectric actuators with corresponding center frequencies were used with matching center frequencies. Along with evaluating mechanical properties and the effects of off-fiber loading, the research team created samples with 3 and 5 wt percent nickel-coated carbon fibers (NCCFs). The researchers noted that although 3D printing of multi-layer samples would have been possible, it was ‘beyond the scope’ of the research; however, six samples were printed for each ultrasound frequency, each at 1 wt percent NCCFs. Ultimately, there were 72 samples 3D printed.

Single-layer materials were fabricated with aligned NCCFs after applying control via the ultrasound field, with the number of parallel lines for aligned NCCF’s figured by ultrasound frequency.

“No significant difference in any of the mechanical properties existed between samples with and without aligned NCCFs, including two separate moduli, ultimate tensile strength, and elongation at failure,” concluded the researchers. “The ultrasound DW technique created flexible single layer samples with integrated lines of aligned NCCFs inspired by biological and natural materials. Using electrically conductive fibers enabled sections of the engineered material to be electrically conductive and, therefore could potentially be used in shielding or other energy applications.”

The study of materials in 3D printing is growing to enormous proportions as researchers refine fabrication processes according to project needs, from exploring large-scale manufacturing solutions with composites to creating bioinks for tissue engineering, water-soluble filaments, and more.

What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Manufacturing bioinspired flexible materials using ultrasound directed self-assembly and 3D printing’]

If you're looking to get architectural 3D animation in the USA, our service provides an exceptional way to bring your architectural concepts to life through dynamic, immersive visuals. Through our platform, you can easily request high-quality 3D animations that showcase your designs in motion, offering a detailed view of your project from multiple angles and perspectives. Whether it's for a real estate development, a commercial building, or an urban planning project, our expert team ensures that every detail is captured in a visually compelling animation.

Through our website, you can seamlessly get architectural 3D animation tailored to your project’s specific needs. With our help, you can offer potential clients or investors an engaging experience that goes beyond static images. By integrating CGI animations with real-world settings, lighting, and textures, our team creates a lifelike experience that allows your audience to interact with your project as though it were already built. This service is perfect for presenting complex designs in a clear, visually attractive way that stands out in the competitive architectural market.