Authors Kirill S. Erokhin, Evgeniy G. Gordeev, and Valentine P. Ananikov, researchers from Zelinsky Institute of Organic Chemistry, Russian Academy of Sciences, delve into a new level of 3D printing science, outlined in the recently published ‘Revealing interactions of layered polymeric materials at solid-liquid interface for building solvent compatibility charts for 3D printing applications.’

Strength and stability in 3D printed parts is an ongoing area of refinement for users today, and researchers have performed a multitude of experiments on materials to figure out how to get better results, creating new algorithms, studying causes and effects on porosity, and ways to eliminate structural defects. This study is centered around the effects of chemicals, however, as the authors evaluate how thermoplastics respond to a variety of solvents.

While there are the obvious challenges in creating nearly any kind of part or prototype, the benefits can be immense in many applications such as medicine and related areas such as tissue engineering, aerospace, automotive, agriculture, and so much more—with the potential for infinite innovation; however, for functional parts being used in critical applications, stability must be ensured. Microstructures may be changed during the printing process, porosity may affect quality, and exposure to organic solvents may cause chemical breakdown.

Materials like polyether ether ketone (PEEK), polyphenylsulfone (PPSU) and polyetherimide (Ultem) may show chemical resistance along with displaying superior mechanical properties, but for most ‘superconstruction materials,’ customized, expensive 3D printers are required to main the high temperatures (350–400 °C) required during successful fabrication:

“Besides, the materials themselves are expensive (as compared with the conventional production-grade thermoplastics), which makes their routine use not very common. Despite the high demand for strong and chemically resistant FDM materials with low shrinkage, the efforts towards their development are still limited,” explain the researchers.

“As an important limitation, 3D printing is poorly suitable for production of plastic objects to be exposed to liquid media. The limitation is due to susceptibility of the plastics to the action of liquid chemicals.”

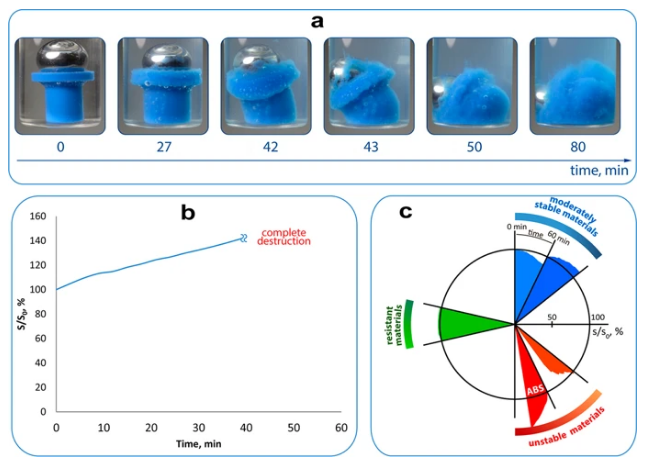

Simple adjustment of printing parameters could offer the solution to creating parts that are more structurally sound though, even with significant exposure to solvents. The authors performed a comparative model experiment with a cylindrical part and an identical 3D printed copy.

As they immersed the parts in DCM, the 3D printed part began to lose its integrity quickly.

Samples were created using a Picaso 3D Designer Pro 250 printer, with the following information provided regarding materials:

“Printing with ABS, SBS, PLA, Nylon, PP, PE, PETG, HIPS, POM, and Primalloy was accomplished at a layer height of 0.2 mm by using a 0.3 mm nozzle. Printing with filled plastics PLA-Cu, Nylon-C, and Ceramo was accomplished by using a 0.5 mm nozzle at a layer height of 0.35 mm.”

Ultimately, 12 different solvents were used:

- Dichloromethane (DCM)

- Tetrahydrofurane (THF)

- Acetone

- Dimethylformamide (DMF)

- Toluene

- Ethyl acetate

- Triethylamine (TEA)

- Acetic acid

- Ethanol

- Sulfuric acid

- Sodium hydroxide

- Water

“The comparison shows that mode of manufacturing (traditional vs. 3D printing) is highly important for the real performance in a contact with liquid,” explained the authors, leaving them to realize that a ‘simple solvent compatibility chart’ would not suffice.

Other polymeric materials were tested as well, with the highest chemical resistance displayed by the following: PP, PE, POM, Nylon, and Nylon-C. Alternately, FDM materials such as PLA, ABS, SBS, and HIPS showed less resistance to solvents.

Primalloy (an elastomer) exhibited ‘moderate resistance,’ while PETG was resistant to acetone and toluene, along with ethyl acetate and DCM.

The main types of destruction noted were disintegration, delamination, molecular dissolution, and swelling—with a ‘destruction scenario’ being noted as the relationship between the thermoplastics and solvents, and differences such as the way PLA becomes dissolved in DCM but delaminated in acetone.

“All tested materials are resistant to water, acidic and basic aqueous solutions, and also to ethanol, which allows their exposure to aqueous reaction media. At the same time, PLA, PLA-Cu, ABS, SBS, Ceramo, HIPS and Primalloy parts are incompatible with acetone, ethyl acetate, toluene, DMF, THF and DCM,” concluded the researchers.

“Resistance of the printed parts to solvents can be increased by three ways. Firstly, the polymers can be modified by additives that would protect them from the solvent action. Secondly, the influence of solvents can be prevented by reasonable choice of 3D printing parameters, as decreased porosity prevents penetration of the solvent. Alternatively, the influence of solvents can be mitigated by adjustment of the part geometry.”

What do you think of this news? Let us know your thoughts; join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Revealing interactions of layered polymeric materials at solid-liquid interface for building solvent compatibility charts for 3D printing applications’]

If you're looking to get architectural 3D animation in the USA, our service provides an exceptional way to bring your architectural concepts to life through dynamic, immersive visuals. Through our platform, you can easily request high-quality 3D animations that showcase your designs in motion, offering a detailed view of your project from multiple angles and perspectives. Whether it's for a real estate development, a commercial building, or an urban planning project, our expert team ensures that every detail is captured in a visually compelling animation.

Through our website, you can seamlessly get architectural 3D animation tailored to your project’s specific needs. With our help, you can offer potential clients or investors an engaging experience that goes beyond static images. By integrating CGI animations with real-world settings, lighting, and textures, our team creates a lifelike experience that allows your audience to interact with your project as though it were already built. This service is perfect for presenting complex designs in a clear, visually attractive way that stands out in the competitive architectural market.