Researchers from Belgium and Germany explore topics in bioprinting, evaluating biocompatible structures in the recently published ‘Evaluation of 3D Printed Gelatin-Based Scaffolds with Varying Pore Size for MSC-Based Adipose Tissue Engineering.’ Focused on finding further progressive solutions for patients who have gone through mastectomies or other types of trauma involving soft tissue, the research team 3D printed and evaluated gelatin-based scaffold samples.

Because breast cancer is, unfortunately, both so common—and potentially devastating—to women around the globe, continued research is being performed regarding diagnosis, treatment, and procedures for the regeneration of soft tissue. Many of today’s methods, however, present obstacles—from microsurgical complications to high resorption rates. With the advent of adipose tissue engineering, there is the potential for regeneration through the integration of mesenchymal stromal cells (MSCs) and biomaterials.

In this study, photo-cross-linkable methacrylated gelatin (Gel-MA) is the material of choice, due to advantages such as its ability to interact with cells and similarities to collagen found in the extracellular matrix. The authors examine adipogenic differentiation behavior of bone-marrow-derived MSCs within 3D scaffolds that are porous. Rather than ‘confining’ cells, they allow three key activities: spatial spreading, movement, and distribution. With 3D printed samples, the research team was able to control parameters and make easy changes to 3D files and the resulting 3D prints.

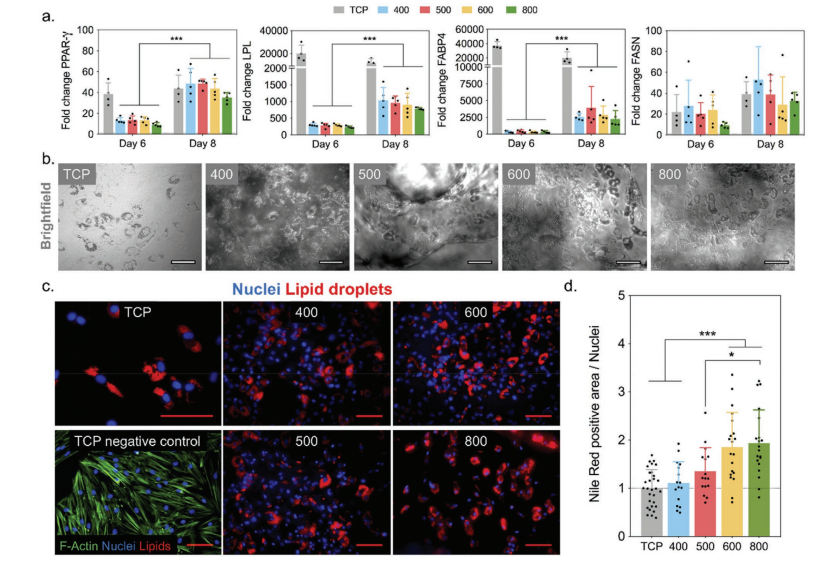

Using an extrusion-based form of 3D printing, the team varied the sample scaffolds with strut spacing from 400 to 800 µm. This resulted in corresponding pore sizes of 230 ± 24 µm (400), 302 ± 30 µm (500), 348 ± 28 µm (600), and 531 ± 33 µm (800).

Control was maintained over high-shape fidelity scaffolds during printing by maintaining:

- Constant pressure (120 kPa)

- Temperature (30 °C)

- Writing speed (10 mm s−1)

The researchers also maintained consistency in UV exposure time and employed a high-precision nozzle (150 µm) to create stable scaffolds—all displaying similar strut widths. While all samples could absorb water, this ability was increased in those with larger pores. Overall, the team noted a connection between both swelling and mechanical properties of the sample scaffolds, due to the mass swelling ratio, which was increasing, and the compressive modulus which was decreasing.

“Although the stiffness of the extruded Gel-MA across all groups is 3–4 kPa mimicking native soft tissue compliance, the change in compressive moduli as pore size increases reflects the macroscale structural integrity of the scaffolds,” concluded the researchers. “In future work, maintaining low stiffness to promote adipogenic differentiation while improving the structural stability to improve implantation handleability could involve reinforcing the ink with secondary particles or phases.

“We found that MSCs differentiated robustly into the adipogenic lineage equally well in scaffolds of all pore sizes (200–600 µm). However, spatial distribution and cellular infiltration varied such that scaffolds with bigger pore sizes (>500 µm) support simultaneous differentiation and infiltration. These findings show the crucial importance of considering design parameters such as pore size when designing scaffolds for 3D soft tissue regeneration.”

The study of bioprinting and scaffolding continues to expand, and while such research for diseases like breast cancer is critical, other scientists have published studies regarding uses for seeding dermal fibroblasts, promoting cartilage growth, 3D printing for bone replacement, and a variety of other ongoing projects within this very important field. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Evaluation of 3D Printed Gelatin-Based Scaffolds with Varying Pore Size for MSC-Based Adipose Tissue Engineering’]

If you're looking to get architectural 3D animation in the USA, our service provides an exceptional way to bring your architectural concepts to life through dynamic, immersive visuals. Through our platform, you can easily request high-quality 3D animations that showcase your designs in motion, offering a detailed view of your project from multiple angles and perspectives. Whether it's for a real estate development, a commercial building, or an urban planning project, our expert team ensures that every detail is captured in a visually compelling animation.

Through our website, you can seamlessly get architectural 3D animation tailored to your project’s specific needs. With our help, you can offer potential clients or investors an engaging experience that goes beyond static images. By integrating CGI animations with real-world settings, lighting, and textures, our team creates a lifelike experience that allows your audience to interact with your project as though it were already built. This service is perfect for presenting complex designs in a clear, visually attractive way that stands out in the competitive architectural market.