Prashanth Ravi brings additional data to light in a recently published study, ‘Understanding the relationship between slicing and measured fill density in material extrusion 3D printing towards precision porosity constructs for biomedical and pharmaceutical applications.’ Helping us to understand more about the effects of slicing and porosity in biomedical applications, Ravi explores basic yet crucial printing parameters like fill density in FDM (FFF, Material Extrusion).

While such topics have been the center of numerous research studies from use with 3D printed medical models, to materials like PLA, and new techniques and settings, in this study Ravi investigated discrepancies and deviations regarding the measured and slicing fill density for smaller-sized prints with low fill and high porosity.

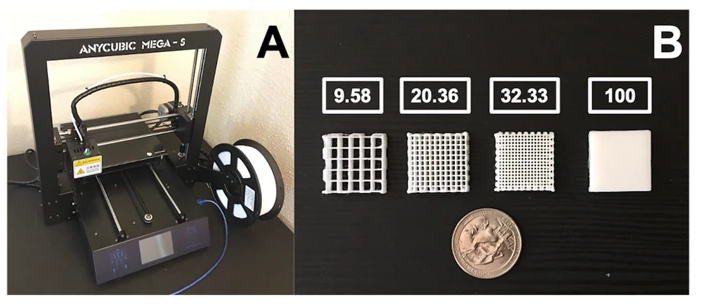

Samples were 3D printed in structures measuring 20mm x 20mm x 5mm with fill density values of 9.58%, 20.36% and 32.33%, in triplicate. An Anycubic Mega-S 3D printer was used for the fabrication of the samples, with PLA as the material of choice.

“A temperature of 220 °C, print speed of 20 mm/sec, LH of 0.2 mm and EW of 0.4 mm were set in the slicer,” explained Ravi. “The fill pattern was set to Rectilinear with 0/90 alternating fill angles and the number of perimeters/outlines was set to 0.

“To ensure proper calibration of the extruder steps a 100% fill density was set in Slic3r and the imported 20 mm × 20 mm × 5 mm STL was printed in triplicates and weighed using a precision digital weighing scale (Newacalox 8028, Newacalox, USA).”

Ravi focused on gaining more understanding regarding error in fill calculations, often arising from ‘discretization of the number of beads in addition to the ignored bead-to-bead interconnect extrusion.’ With the fill densities reduced, Ravi found that that the number of extruded beads was reduced too.

“Such a trial and error approach was necessary because Slic3r performs an internal scaling of the part size before generating n,” noted Ravi.

Triplicate samples were also printed at 15% and 40% Slic3r fill density for further confirmation of the approach.

Ultimately, Ravi found that the measured fill density percentage was as much as 3.5 percent greater than that of the Slic3r fill density percent.

“At low fill densities the measured fill density was found to deviate substantially from the slicing fill density with average absolute errors greater than 26% in certain instances for a 20 mm × 20 mm × 5 mm cuboidal construct. The predictive fill density percent model in the study estimated fill density to well within 5% of the measured fill density percent values at all five low fill density settings, since the model is based on the actual slicer (Slic3r) toolpath and takes into account the material extruded in the bead-to-bead interconnects,” concluded Ravi.

“The approach presented in this study could be used to predict construct fill density with reasonable accuracy based on slicing parameters in Slic3r. The methodology could prove useful in biomedical and pharmaceutical applications requiring accurate control of fill density for relatively small sized constructs to meet targeted functional criteria such as compressive strength and content release rate.”

What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Understanding the relationship between slicing and measured fill density in material extrusion 3D printing towards precision porosity constructs for biomedical and pharmaceutical applications’]

If you're looking to get architectural 3D animation in the USA, our service provides an exceptional way to bring your architectural concepts to life through dynamic, immersive visuals. Through our platform, you can easily request high-quality 3D animations that showcase your designs in motion, offering a detailed view of your project from multiple angles and perspectives. Whether it's for a real estate development, a commercial building, or an urban planning project, our expert team ensures that every detail is captured in a visually compelling animation.

Through our website, you can seamlessly get architectural 3D animation tailored to your project’s specific needs. With our help, you can offer potential clients or investors an engaging experience that goes beyond static images. By integrating CGI animations with real-world settings, lighting, and textures, our team creates a lifelike experience that allows your audience to interact with your project as though it were already built. This service is perfect for presenting complex designs in a clear, visually attractive way that stands out in the competitive architectural market.